Oxnard, CA

Stroube Drain

Scope/Solutions

After constructing the first 1.5 mi of the Stroube Drain cast-in-place, reinforced concrete box culvert, the owner discovered the design did not consider live loads for the most severe traffic orientation. The owner wanted to know if cracking they observed resulted from a design issue and if it would affect durability. SGH evaluated the structural adequacy and durability of the as-built culvert and also served as a neutral party with binding rulings during the dispute resolution.

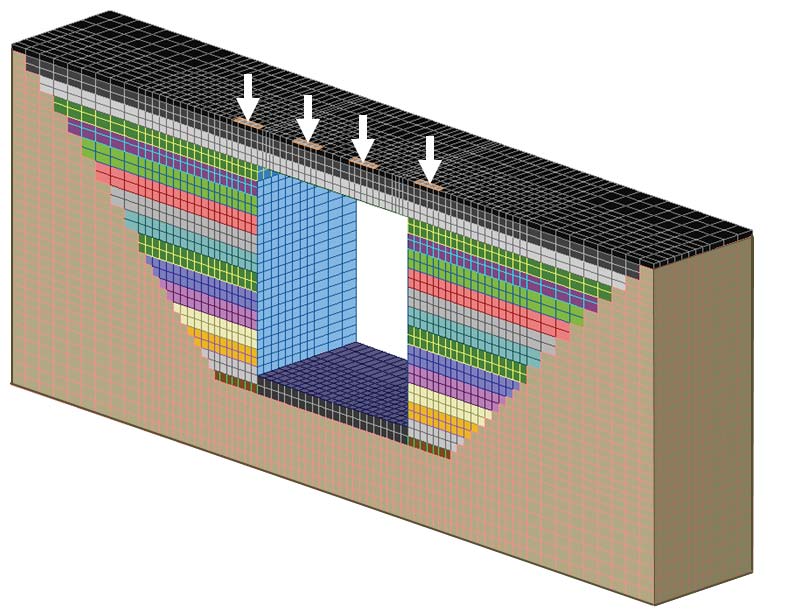

SGH visited the site and performed an internal inspection to document the condition of the 10 ft span by 10 ft rise culvert. We studied construction records, reviewed governing and other industry design standards, and performed calculations to demonstrate the as-built strength and adequacy of the culvert for the more severe loading condition. Highlights of our evaluation include the following:

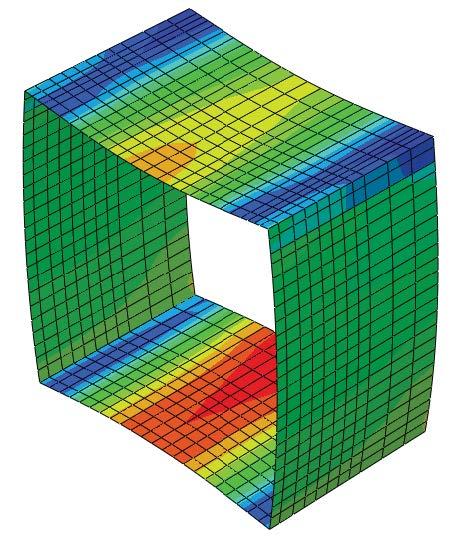

- Performed two- and three-dimensional finite element modeling of various culvert sections

- Compared reinforcement sizes, cover, and spacing in the as-built culvert to the design

- Assessed the culvert’s structural adequacy based on code provisions and more refined methods to determine the as-constructed level of safety

- Investigated the root causes of the cracking we observed and evaluated if the cracking would affect durability

- Provided recommendations for improving the governing design specification for live load application and for controlling cracking in reinforced concrete sections

SGH concluded that the drain was safe and is expected to provide good structural performance throughout its design life. Our findings led the owner and developer to a legally binding dispute resolution and helped the project salvage approximately 10,000 cu yd of concrete, avoiding schedule delays associated with having to reconstruct portions of the culvert.

Project Summary

Key team members