Roslindale, MA

MWRA, High Level Sewer

Scope/Solutions

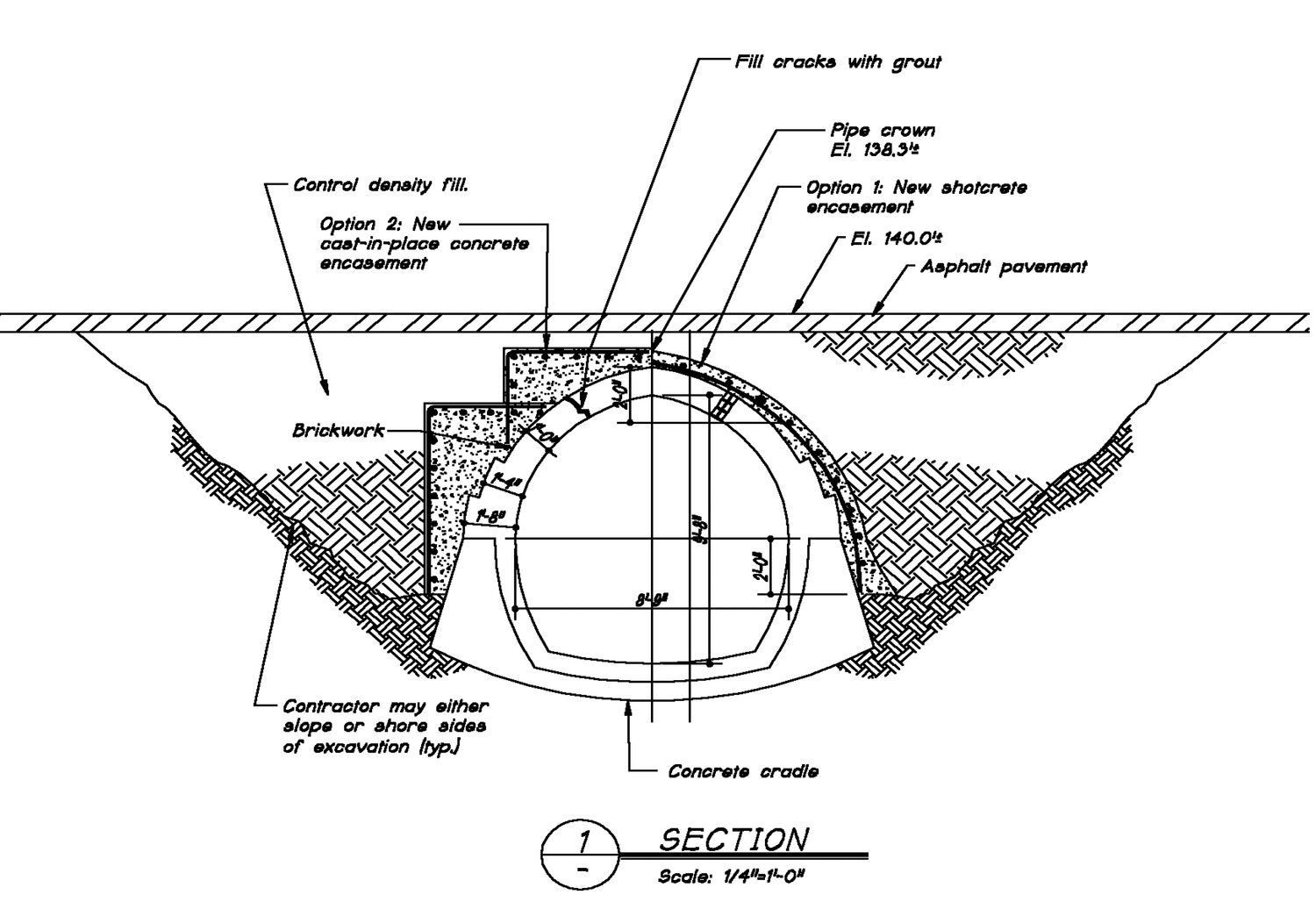

The High Level Sewer (HLS) is a masonry conduit built around 1901. Following a large rainstorm, the HLS developed internal pressure that caused water to overflow through the manholes and flood parts of the Roslindale neighborhood. The manholes were bolted down to prevent future flooding. A couple years later, during a heavy rain storm, the HLS was pressurized again, resulting in failures of manholes, cracking of the masonry conduit, movement and cracking at bends in the sewer line, and significant leakage. SGH was retained to perform an emergency condition assessment, evaluate risk of pressurization during future storm events, and develop a repair program.

Highlights of our work on this project include the following:

- Performed manned internal inspection of approximately 1,600 ft of HLS while in operation

- Inspected the exterior of the HLS in eight test pit excavations

- Evaluated rainfall data and hydraulic analysis before and after a connection bypass to Stony Brook planned by MWRA to lower water levels during a severe storm

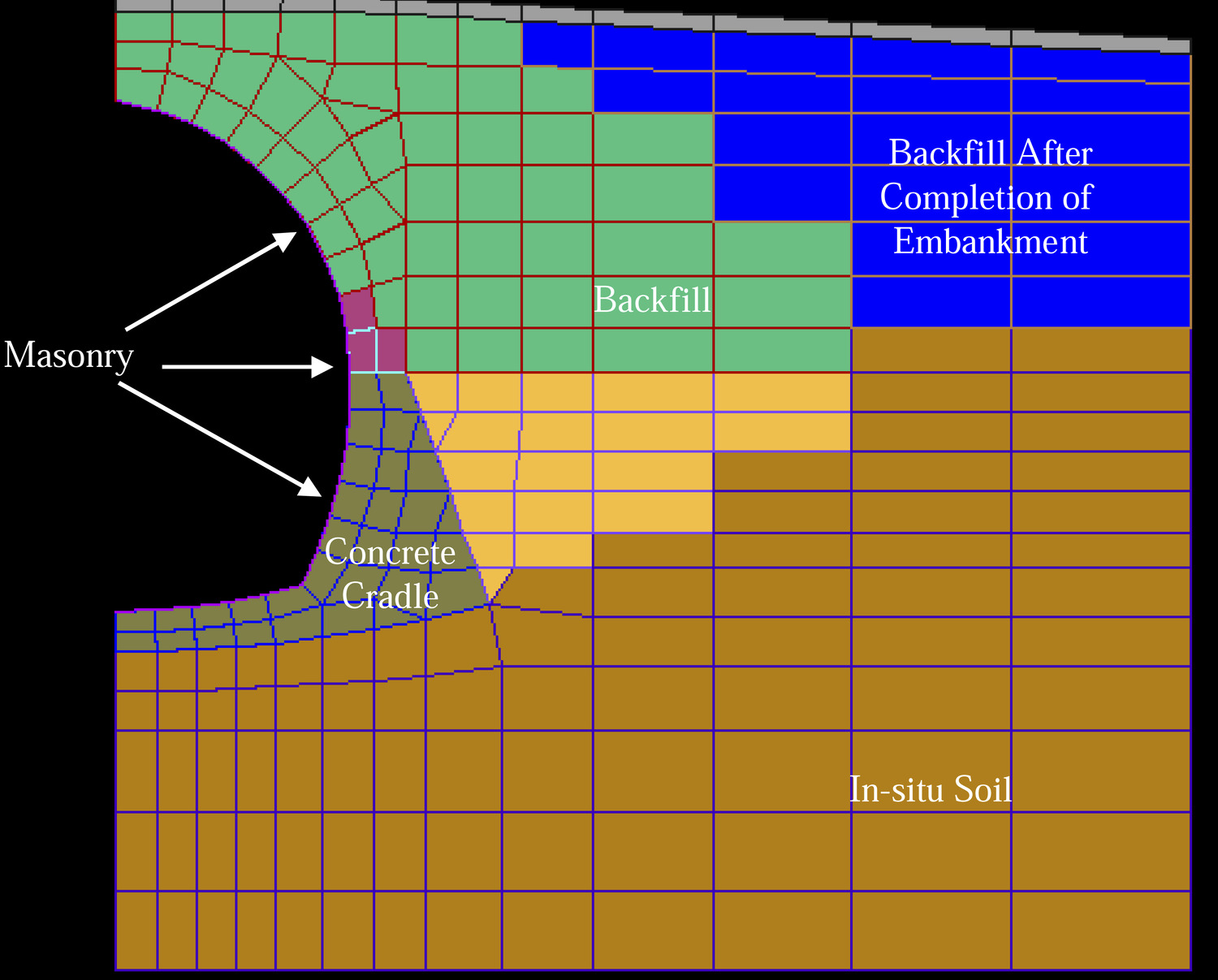

- Performed structural evaluation and damage assessment of the conduit by finite-element soil-structure interaction analysis

- Determined risk associated with pressurization of the HLS in future storms before bypass installation

- Developed an emergency response procedure

- Identified two areas that needed emergency repairs, prepared design and bid documents, hired the contractor, performed bid evaluations, and monitored construction

Project Summary

Solutions

Failure Investigation

Services

Structures | Advanced Analysis

Markets

Infrastructure & Transportation

Client(s)

Massachusetts Water Resource Authority

Specialized Capabilities

Repair & Strengthening | Buried Infrastructure | Computational Mechanics

Key team members

Additional Projects

Northeast

Logan International Airport Terminal E

After the contractor placed the 4 in. thick overlay, they observed lifted slab edges, cracks, and hollow-sounding areas in some locations. The contractor retained SGH to investigate the problem and provide repair options.

Northeast

Development of Locomotive Crashworthy Components

Train collisions involving locomotives can result in serious damage and occupant injury due to the larger size and stiffness of the locomotive. SGH assisted TIAX, LLC and the Volpe Center with designing a crash energy management system for a locomotive along with material and component testing.