Idaho Falls, ID

Idaho National Laboratory, Fuel Manufacturing Facility (FMF)

Scope/Solutions

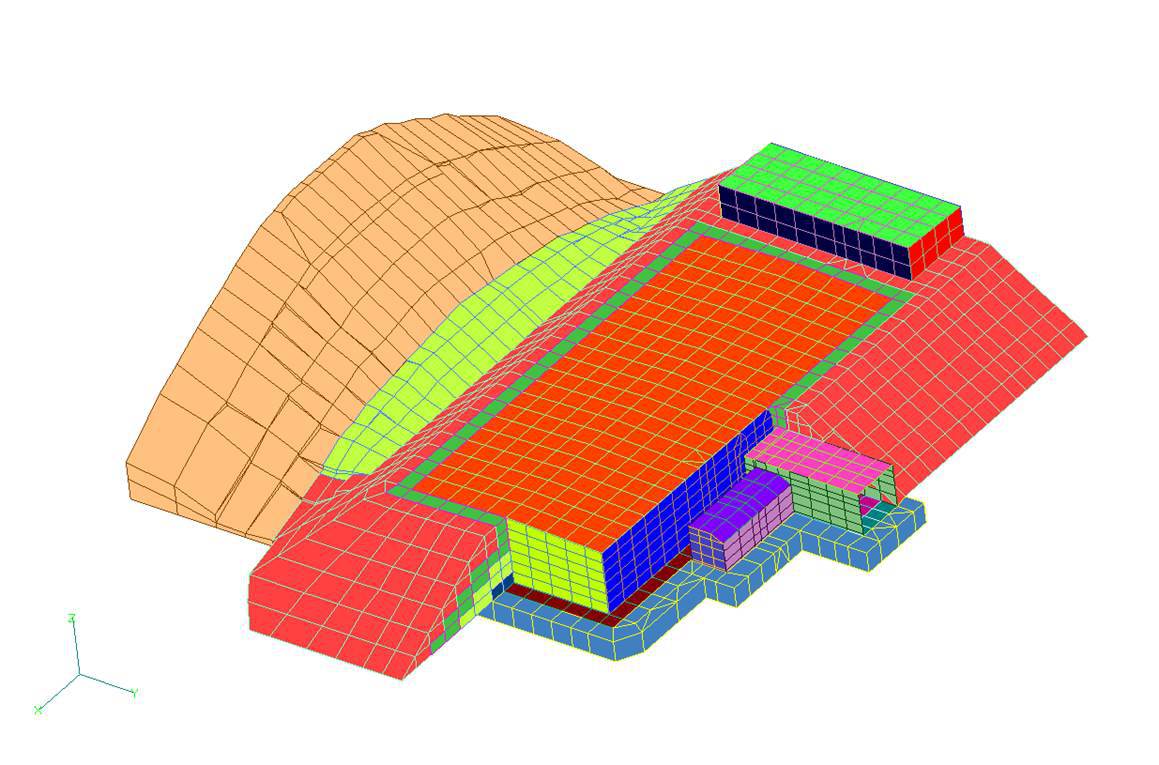

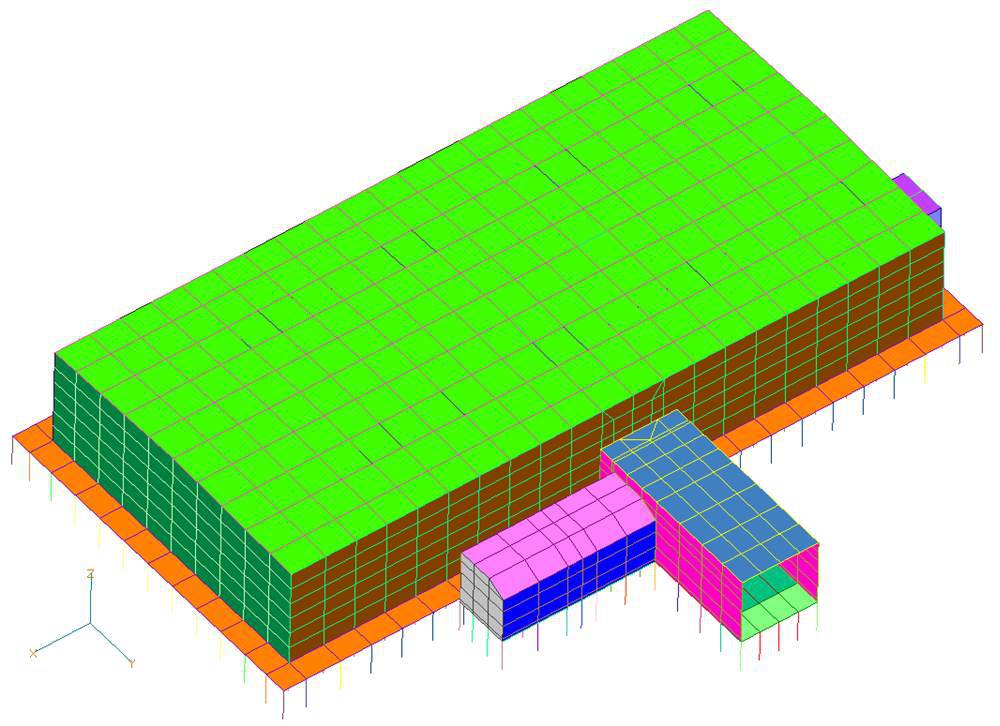

Changes to Department of Energy (DOE) codes required Idaho National Laboratory (INL) to reevaluate and retrofit its Fuel Manufacturing Facility (FMF) at the Materials and Fuels Complex. The FMF has reinforced concrete exterior walls and slabs with reinforced concrete masonry interior walls. The structure lies on shallow soil above bedrock and under a berm. In a two-phase project, SGH provided assessment and design services for Battelle Energy Alliance, LLC (BEA), which operates the facility for the Department of Energy.

In the Phase I structural evaluation using modern codes, SGH:

- Performed a condition assessment of the facility and its connecting corridors in accordance with DOE-STD-1020 seismic requirements for Performance Category 3 (PC-3)/Seismic Design Category 3C (SDC-3C)

- Conducted a seismic soil-structure interaction analysis of the FMF and the berm using SASSI

- Evaluated the capacity of the base slab for support of additional racks

- Presented seismic analysis and structural evaluation presentations to independent reviewers

For the Phase II design retrofit using modern codes, SGH:

- Reviewed the analysis and design of new racks

- Designed upgrades that allowed the facility to meet PC-3/SDC-3C requirements

- Prepared design drawings and specifications

- Provided construction administration services

Project Summary

Solutions

Repair & Rehabilitation

Services

Structures | Advanced Analysis

Markets

Science & Defense

Client(s)

Battelle Energy Alliance, LLC

Specialized Capabilities

Seismic Engineering | Repair & Strengthening | Nuclear

Key team members

Additional Projects

West

Idaho National Laboratory, Fuel Manufacturing Facility (MFC-704), Seismic Fragility Evaluation

SGH developed seismic fragilities for the MFC-704 structure (also referred to as the Fuel Manufacturing Facility) for input to a seismic probabilistic risk assessment.

West

Idaho National Laboratory, Integrated Waste Treatment Unit (IWTU)

As engineer of record, SGH designed two of the primary buildings to accommodate the system and supported completion of the project on an expedited schedule.