Greybull, WY

Greybull Water Transmission Pipeline

Scope/Solutions

The Greybull Water Transmission Pipeline is the only pipeline that carries treated water for the town of Greybull. The 16.5 mile pipeline was constructed in 1960s and 1970s with 12 in. and 14 in. dia. asbestos cement (AC) pipes. SGH performed a condition assessment of this pipeline as a part of the town’s maintenance program.

AC pipe can fail as a result of stresses and strains in the pipe wall or near joints or due to internal or external chemical degradation of material and reduction of capacities. As a part of the ongoing project, SGH:

- Performed the condition assessment of the pipelines without removing the line from service

- Conducted geological, geotechnical, and groundwater investigations; and chemical testing and analysis to determine corrosivity of environment and internal water to AC pipe

- Evaluated failure risk parameters along the pipeline

- Made external test pit inspections of pipe at ten locations, hot tapping to remove samples of pipe wall

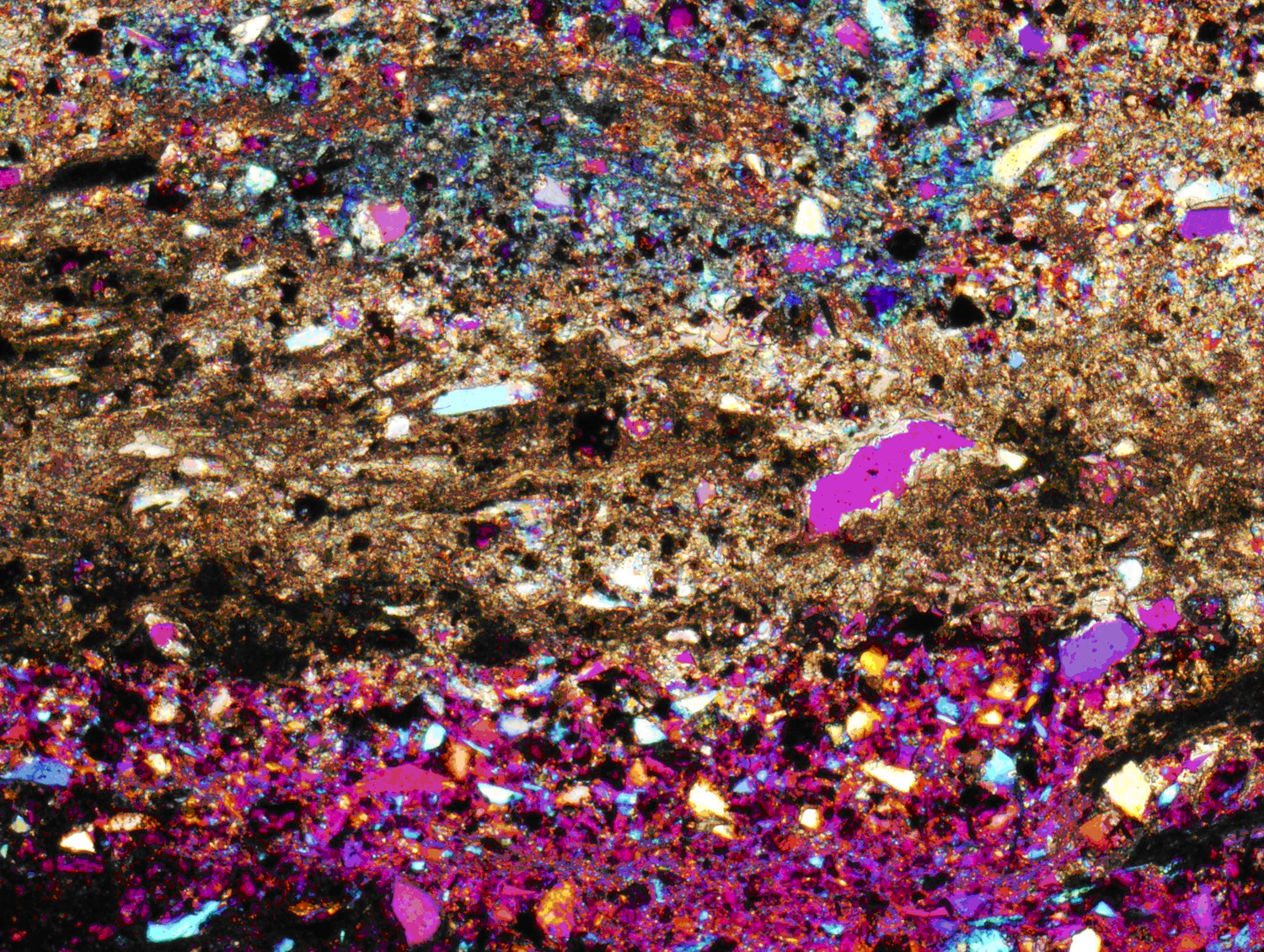

- Determined degradation mechanisms and the extent of degradation of the pipe wall using petrographic analysis

- Conducted axial and bending strength tests of AC pipe material

- Performed transient surge analysis

- Evaluated the AC pipe for internal pressure, soil, and live loads

- Analyzed failure risk of pipe considering loss of pipe wall section due to material degradation

Project Summary

Solutions

Repair & Rehabilitation

Services

Structures | Advanced Analysis | Performance & Code Consulting

Markets

Infrastructure & Transportation

Client(s)

Wyoming Groundwater, LLC

Specialized Capabilities

Geotechnical | Buried Infrastructure | Risk & Resilience Assessment | Materials Science | Microscopy

Additional Projects

West

Jack London Square Boardwalk

After leasing a section of the boardwalk from the Port of Oakland, the developer wanted to assess the condition of a portion of the boardwalk. SGH was the prime and structural engineer for the assessment.

West

Golden Gate Bridge North Anchorage Housing

The District determined the bridge could not reliably survive a repeat of the Great 1906 San Francisco earthquake and elected to undertake a multi-phase retrofit of the structure and foundations.