Waltham, MA

Galvanic Testing of Materials

Scope/Solutions

Contact between dissimilar metals can lead to accelerated deterioration due to galvanic corrosion. Standard sample Galvanic Series charts (e.g., ASTM G82) provide general guidelines for compatibility. However, most of these charts are based on studies performed by the Navy for exposure to seawater submersion and do not include many of the available alloys and coatings used in building construction. SGH is conducting ongoing, long-term testing on combinations of metals and metallic coatings to evaluate the severity of galvanic corrosion and the potential for staining.

In the winter of 2000, SGH started the testing program for metals and metallic coatings often used in architectural applications. Our testing includes the following metals:

- Galvanized steel (G90)

- Copper

- Lead-coated copper

- Aluminum

- Anodized Aluminum

- Aluminum/zinc coating on steel

- Stainless steel (Type 304)

- Tin/zinc alloy coating over stainless steel

- Tin/zinc alloy coating over copper

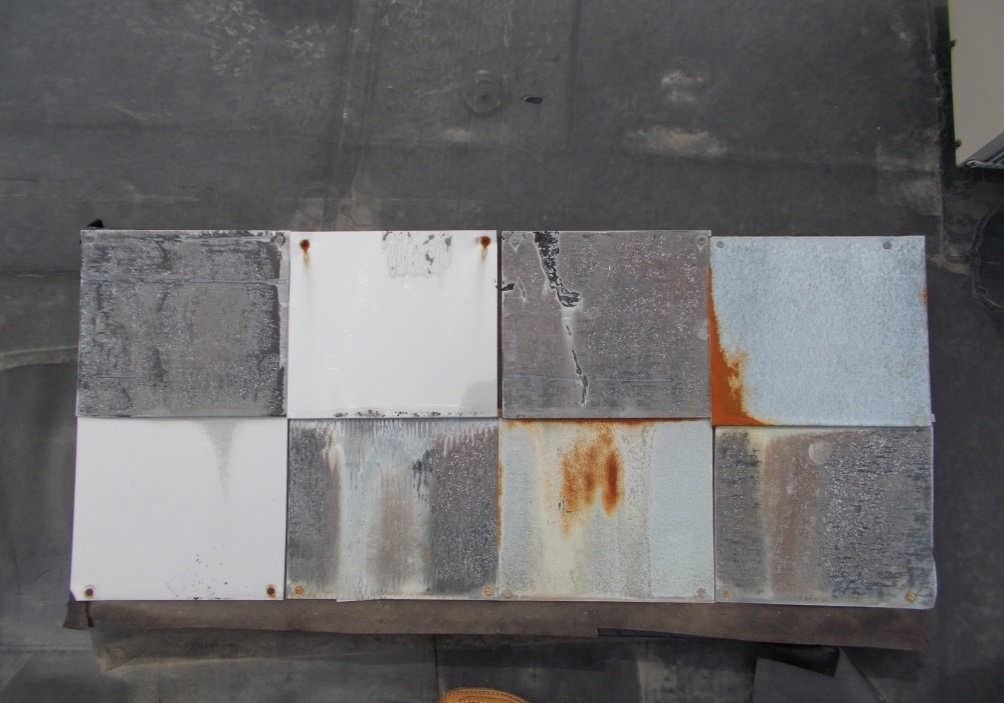

SGH prepared 1 sq ft metal pieces and loose-locked pairs of metal pieces with a hem. We assembled two samples for every metal pair, alternating the top and bottom piece, and installed them on wood panels sloped at 10° from horizontal. After 15 yrs on our office roof in Massachusetts, we evaluated staining patterns and extent of corrosion and found certain combinations do not follow trends in the Galvanic Series charts. Based on our research, SGH developed a reference chart summarizing the results and providing guidance to our staff designing and investigating building materials and assemblies.

In collaboration with Saracen Properties (building owner).

Project Summary

Key team members