Alberta, AB

CNRL Supermodules, Horizon Oil Sands Delayed Coker Unit Expansion, Fort McMurray

Scope/Solutions

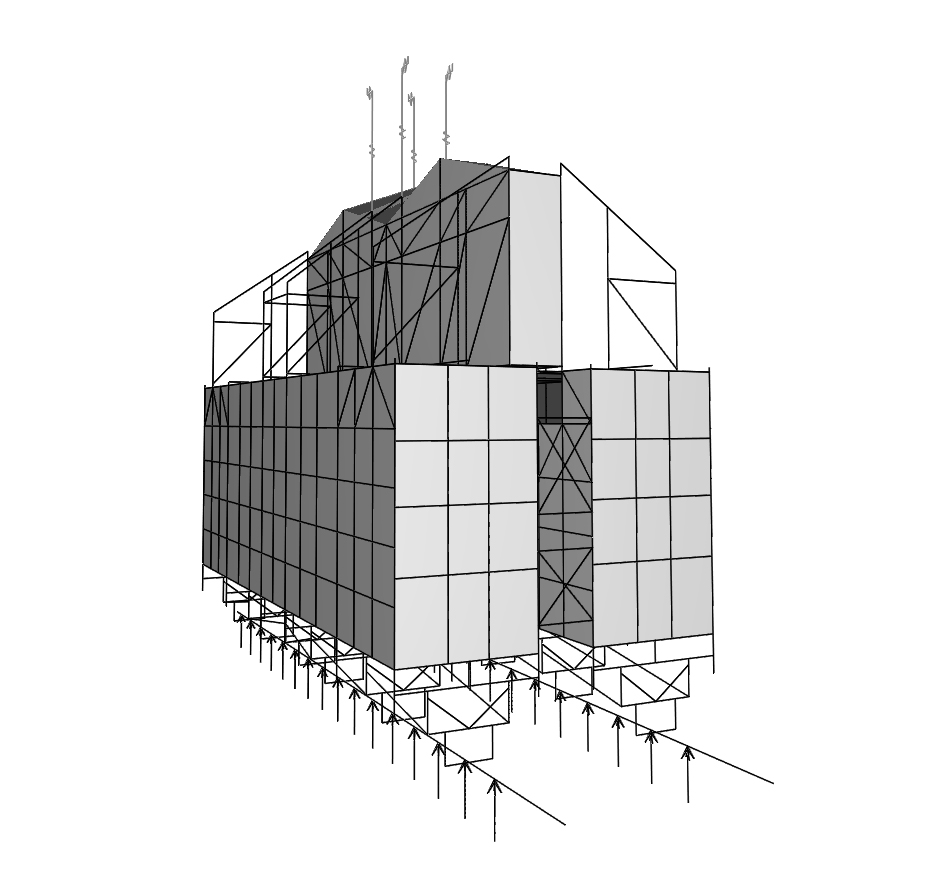

With modular construction, CNRL was able to expand the Delayed Coker Unit at their Horizon Oil Sands site while minimizing downtime during construction. The project utilized supermodule structures constructed or assembled from smaller modules near the plant, transported to the plant on one or two rows of self-propelled modular transporters (SPMTs), and hoisted into place by a large crane. CNRL retained SGH to peer review transport/lifting plans and evaluate the structural adequacy of the supermodules during transport and lifting.

SGH evaluated the strength of the supermodules under loads imposed during the planned transport and lifting, and compared effects of the transport and lifting with the original engineering assumptions. We evaluated seven supermodules, which weighed up to 795 tons and were up to 130 ft long. Working closely with CNRL, we evaluated the following:

- Structural adequacy of the supermodules

- Stability of supermodules on the SPMTs

- Behavior and interaction of supermodule with the rigging system

- Suitability of the roadways to support the SPMT loading

- Roadway clearances and geometry

- Structural adequacy of connections

We identified adjustments that CNRL could implement to mitigate risk. Our recommendations included the following:

- Strengthening certain connections to resist calculated loads that we provided to CNRL

- Implementing a detailed inspection and testing protocol that we developed for highly-stressed connections in each supermodule to increase confidence in the connection performance

- Adding temporary bracing to strengthen and stiffen certain supermodules

- Modifying SPMT suspension fields and the spacing between SPMT rows to increase stability during transport

Project Summary

Key team members