Embodied Carbon in Structures: Reducing Environmental Impact in the AEC Industry

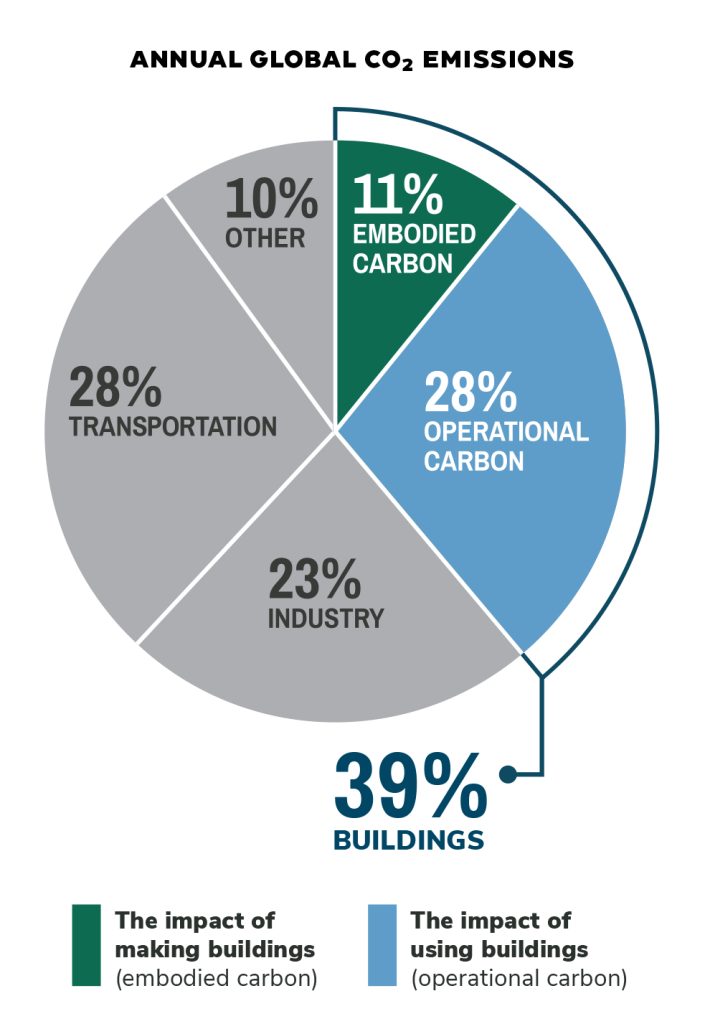

The built environment plays a substantial role in global energy consumption, with nearly 40% of global greenhouse gas emissions coming from building projects, according to the Global Alliance for Buildings and Construction. There are many things that advocates and practitioners in the architecture, engineering, and construction (AEC) industry can do to address this issue and respond to the growing effects of climate change.

For decades, we have focused on lowering operational carbon in buildings by decreasing energy usage and improving efficiency. More recently, however, we recognize the importance of tracking and reducing the embodied carbon associated with making the buildings themselves. To truly make a difference, building owners, design partners, and construction officials need to consider the role that embodied carbon plays in our projects, understand methods for tracking, measuring, and reducing embodied carbon, and take part in the ongoing industry discussion to combat this issue.

Source: Global Alliance for Buildings and Construction, “Global Status Report 2017“

What Is Embodied Carbon?

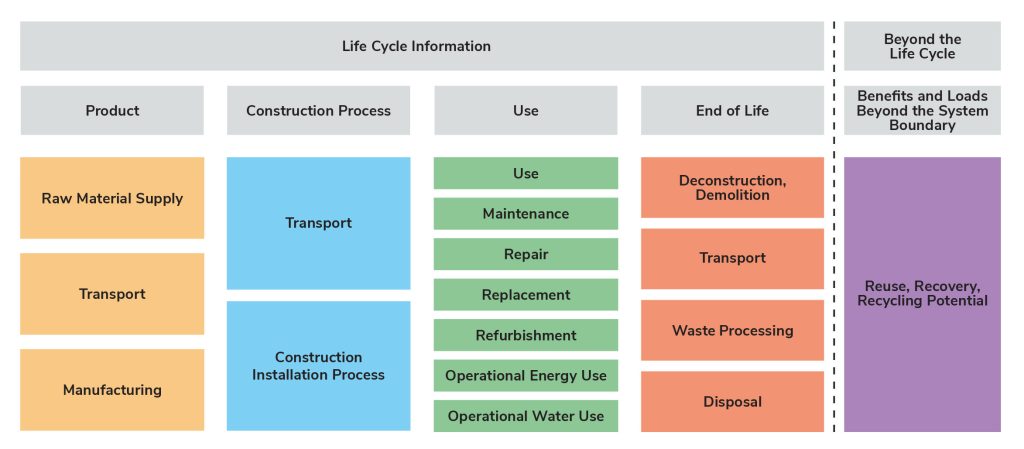

Embodied carbon refers to the materials-related carbon dioxide (CO2) emissions associated with the entire life cycle of a building, from raw material extraction and transportation to construction, maintenance, and eventual demolition. Embodied carbon differs from operational emissions, which are generated during a building’s day-to-day operation, such as by heating, cooling, and lighting. Understanding the significance of embodied carbon in design or retrofit discussions is crucial because it means that a building’s environmental impact is not limited to just its use. The materials we choose and the construction processes we employ contribute to a building’s carbon footprint on top of its use-phase emissions. And crucially, these embodied emissions happen up-front, out-weighing use-phase emissions of new construction over the next several decades when we need to reduce carbon emissions to zero.

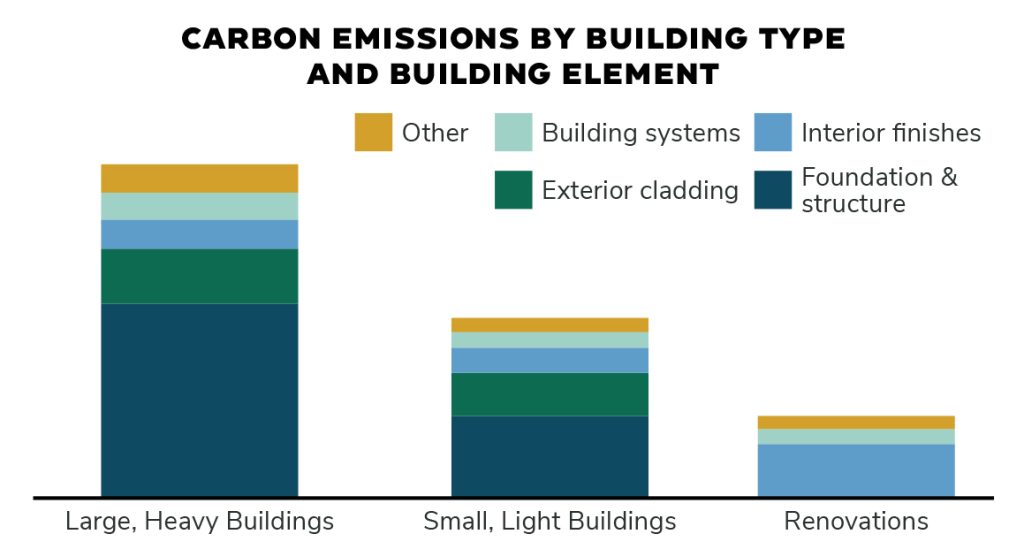

Structural and building enclosure materials generally account for well over half of the embodied carbon on new design and renovation projects. They also represent the greatest opportunity for reducing a building’s overall embodied carbon footprint—how we specify materials, what types of gravity and lateral systems we recommend, and what types of facade and insulation we select make a difference.

Source: Carbon Leadership Forum, “The Time Value of Carbon“

How Do We Measure Embodied Carbon?

There are several key tools and approaches to measuring embodied carbon, including:

- Life cycle assessments (LCA): LCAs evaluate the environmental impact of a product or system during all or part of its life, allowing AEC professionals to quantify the embodied carbon of a building and identify areas for improvement.

Source: iStructe, The Structural Engineer, “A Brief Guide to Calculating Embodied Carbon“

- Environmental product declarations (EPD): These standardized documents communicate the environmental performance of a building material or product to inform decision-making processes by providing transparent and standardized information. Project-specific EPDs are more precise for the material being used on a given project. If unavailable, industry-average EPDs can be used in their place in the analysis.

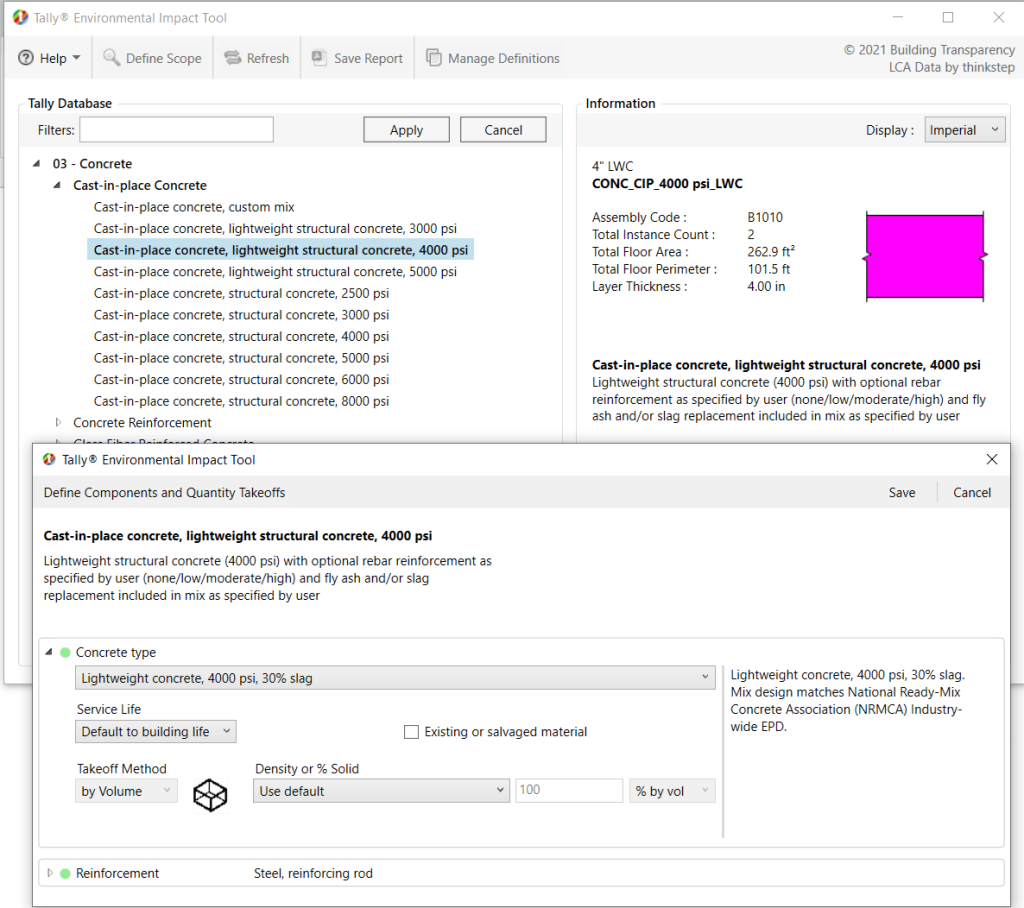

- Modeling software and benchmarking tools: To assess embodied carbon decisions, designers can use tracking tools in combination with building information modeling (BIM) software and other approaches to estimate a project’s carbon footprint based on the materials and construction methods chosen. This information can be used in benchmarking tools to compare carbon performance for a project to industry baselines and best practices.

Embodied carbon Revit plugins quantify the building materials and architectural products that structures will contain.

Embodied carbon is often reported as Global Warming Potential (GWP) in units of kilograms of carbon dioxide equivalent (CO2e).

Case in Point: Quantifying Embodied Carbon in Campus Concrete

To illustrate the significance of embodied carbon and the impact it can have on construction projects, our structural engineering teams have quantified the embodied carbon of many structural designs, including a new science building on a university campus in New England.

In this example, the project team and owner recognized the importance of reducing embodied carbon during design development. The SGH team quickly identified concrete as a major factor in the embodied carbon of the building.

The team developed and adopted several carbon reduction strategies, including:

- Supplemental cementitious material (SCM): The team increased the amount of SCMs in all concrete mix designs, reducing the amount of portland cement, which is the largest contributor to embodied carbon in concrete.

- Design optimization: The building’s design was optimized to reduce the overall quantity of materials needed, further lowering its embodied carbon. The decisions included specifying lower-strength concrete, which typically has a lower GWP than higher strengths. The team studied if lowering the strength of the concrete would increase the amount of concrete on the project (and potentially the overall GWP). However, we found that any increases in concrete member sizes were offset by the GWP savings from the lower concrete strength and an overall reduction in GWP for concrete elements.

The project team’s commitment to addressing embodied carbon resulted in a structure with reduced environmental impact that also showcased sustainable construction practices. The initiatives reduced the global warming potential of the concrete by 30% from the initial project specifications. The lessons learned from this case study can serve as a valuable blueprint for future projects in the AEC industry.

Taking Action with SE 2050

The Structural Engineering Institute’s Structural Engineers 2050 Commitment program (SE 2050) sets out to reduce embodied carbon in structural systems to net zero by the year 2050. SGH is a signatory member of the SE 2050 program, regularly reports our progress, and advocates for others in the industry to follow suit. Structural engineers play a pivotal role in addressing embodied carbon and must embrace sustainable design practices and advocate for low-carbon solutions in the construction industry. By collaborating with architects, contractors, and other stakeholders, structural engineers can drive the industry’s transformation towards a more sustainable future.

Conclusion

In the fight against climate change, the AEC industry must recognize the significance of embodied carbon in structures and take proactive steps to address this issue. By understanding the issue, tracking and measuring its impact, and collaborating with project partners to make informed decisions, we can help achieve carbon neutrality and create a built environment that is both functional and sustainable for generations to come.