Digital Design, Coordination, and Delivery

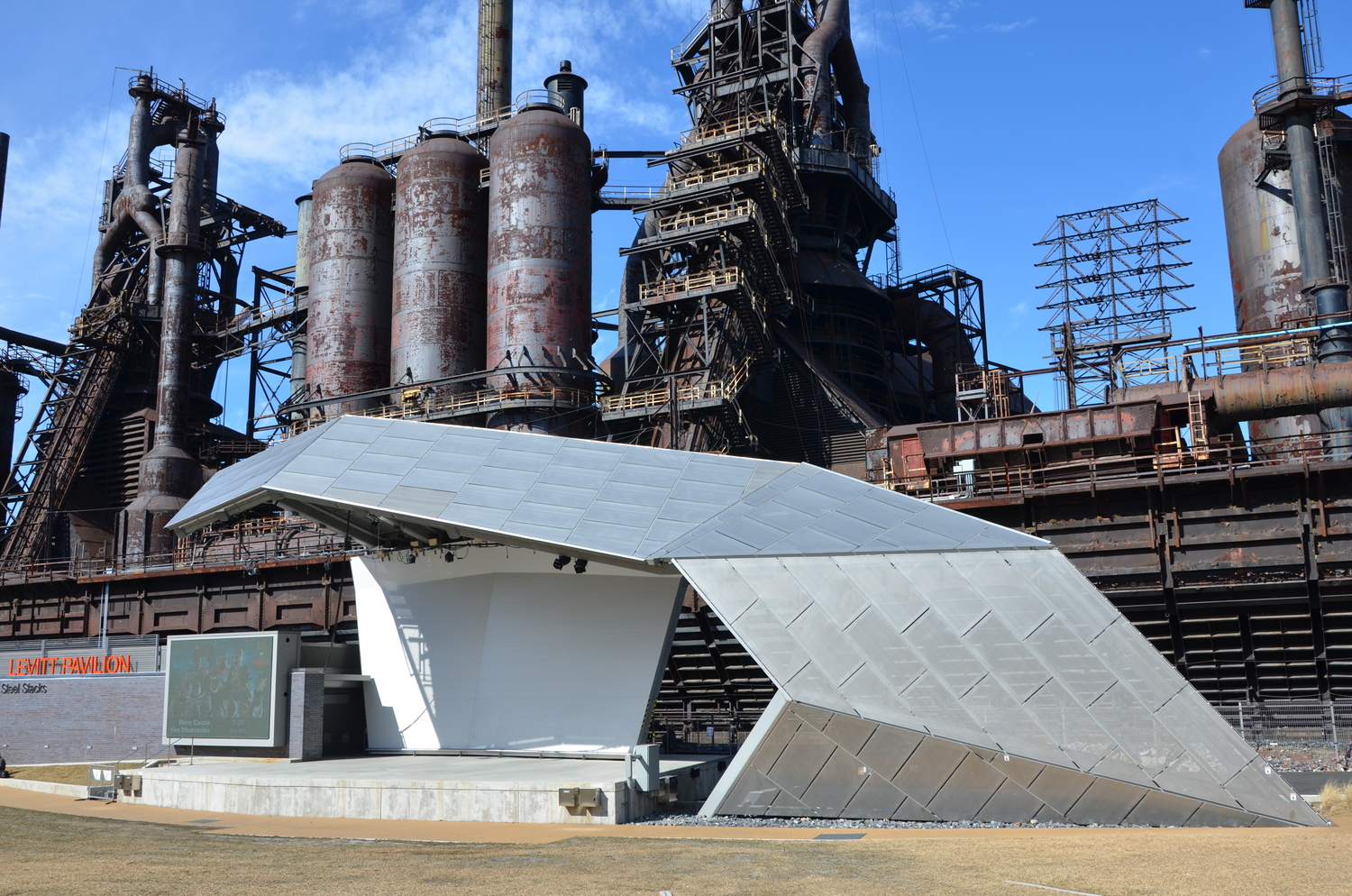

Methods for digital design, coordination, and delivery are prevalent in the building design and construction industry. As tools and knowledge evolve, new software applications present themselves on a broad range of projects. Modeling software is especially relevant to structural designers, who can use the software to optimize material quantities, improve coordination, and streamline execution for projects with complex geometry.

NEW SOFTWARE IN AN EVOLVING INDUSTRY

Recognizing the vast potential of digital design, coordination, and delivery, software developers are targeting a broader sector of architectural, engineering, and construction (A/E/C) markets. Common modeling software includes a variety of tools, each with a place in production and execution cycles. Examples of modeling software include Google SketchUp, Autodesk Revit, Rhinoceros, Dassault Systemès Solidworks, and Trimble’s multi-material fabrication software (Tekla).

As more readily available and user‑friendly programs hit the market, the building design industry is exploring possibilities made available with these tools. The evolution is slowly changing the way we design, coordinate, deliver, and fabricate buildings and building systems.

As technology becomes more sophisticated and widespread, project teams experienced with emerging modeling software tools and their capabilities are critical to advancing the design and construction process.

DESIGN WORKFLOW

Ideally, the project workflow includes developing a design-intent (architectural and/or structural) model, transferring the design-intent model to a structural analysis modeling program, and converting the design‑intent model into a delivery/fabrication model.

At the early stages of a project, a model is a valuable tool facilitating spatial coordination. Although the design-intent model is created by the architect or artist, the structural engineer plays an important role throughout the modeling process. The structural engineer can contribute to the design-intent model by reviewing geometry, performing preliminary structural analyses, and providing sketches of components and details to facilitate the architectural development.

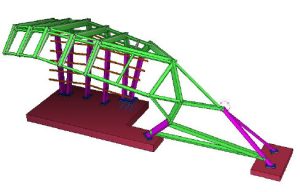

- RISA 3D analytical model

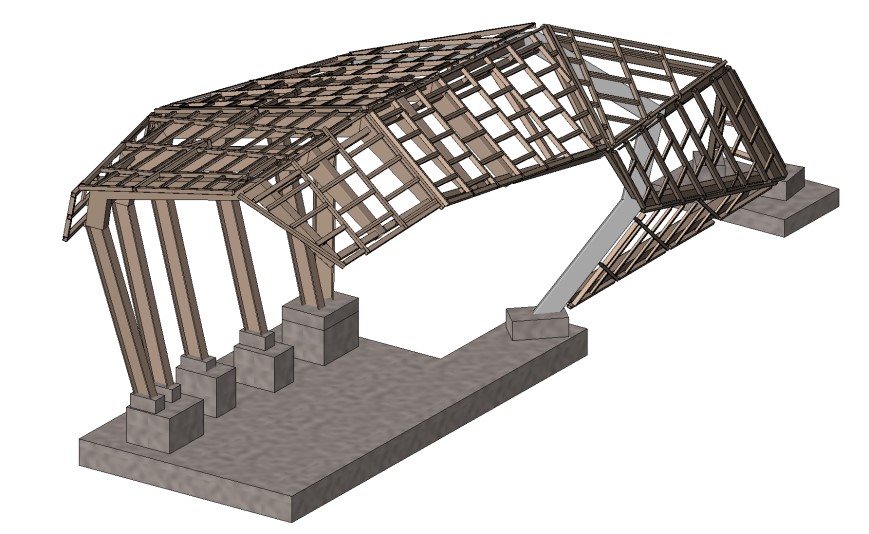

- Steel fabrication model

FABRICATION AND PRODUCTION

In later stages of the project, the contractor can use models to fabricate components or formwork. This type of work is sometimes referred to as mass customization. Mass customization capitalizes on developing complex geometric systems by computer modeling and using computer‑numerically controlled (CNC) fabrication to significantly reduce labor during fabrication. Examples of fabrication methods include digital printers, multi-axis routers, water-jet cutting, laser cutting, robotically controlled hot‑wire cutting, concrete formwork fabrication, and structural steel fabrication. Many of these tools are now standard in university architectural departments and architectural design firms, representing future opportunities for digital design-to-fabrication. Commercially, the steel industry has been using digital tools for some time, and the concrete industry is now using these types of tools for formwork fabrication.

COORDINATION

Defining modeling objectives early in the process is crucial. The model will require more detail the further it is used throughout the coordination/analysis/fabrication process. The project team should consider this required level of detail along with the structure’s geometric complexity when selecting software.

Successful modeling efforts stem from the commitment and ingenuity of the design team. As technology becomes more sophisticated and widespread, project teams experienced with emerging modeling software tools and their capabilities are critical to advancing the design and construction process.