Understanding Seismic Certification Requirements for Nonstructural Components

Seismic certification for nonstructural components is essential for ensuring that various types of equipment and systems can withstand the forces generated by earthquakes. For equipment manufacturers, building owners, and facility managers, understanding this process is key to maintaining the integrity, safety, and operability of their facilities, particularly in earthquake-prone areas. This is especially true for mission-critical facilities like hospitals and health care facilities that need to be operational following a design earthquake event.

Project teams should be well-versed in these requirements and partner with experienced structural engineers and seismic certification consultants to determine key aspects of seismic certification and take the necessary steps to ensure compliance.

What Is Seismic Certification?

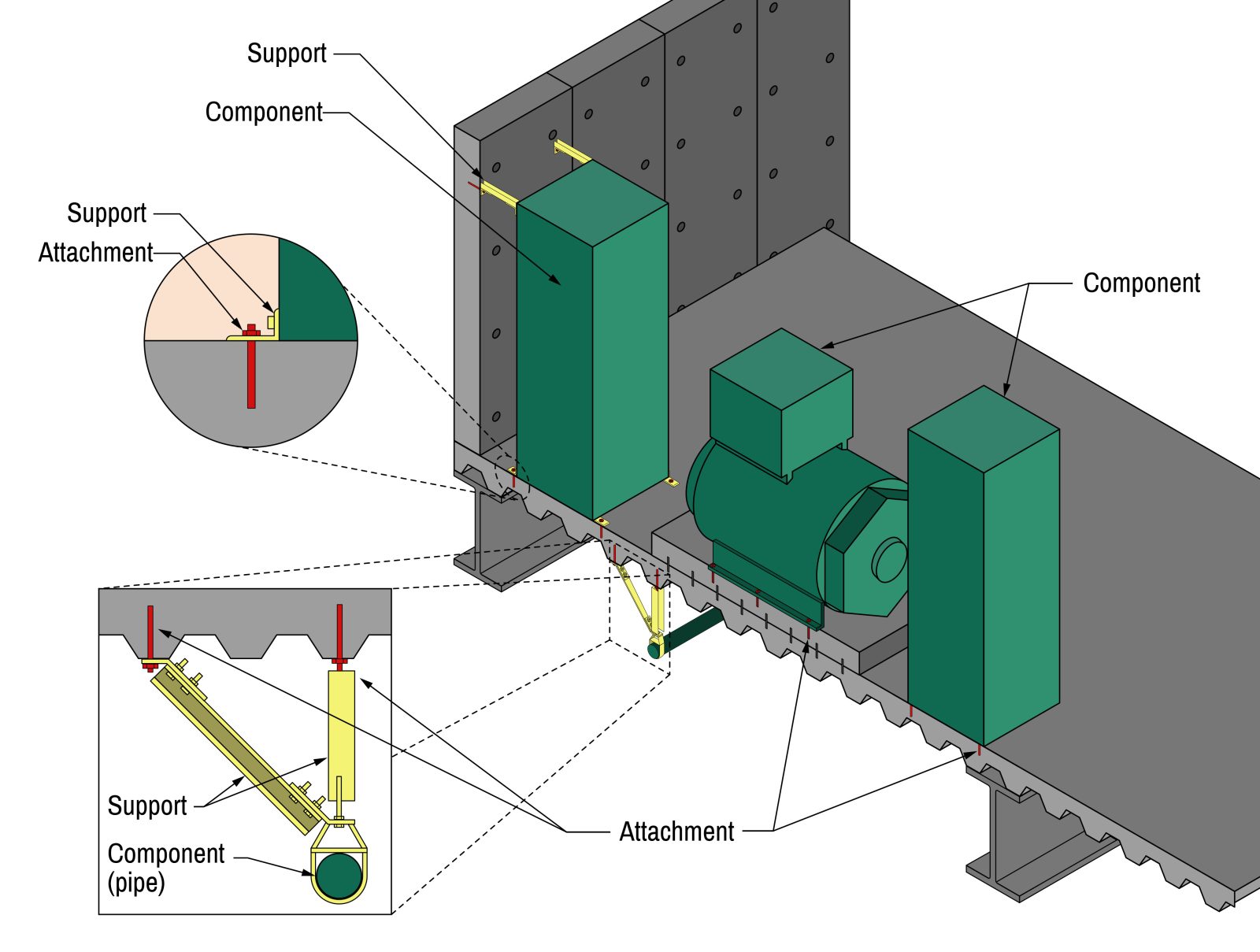

Seismic certification is a process in which nonstructural components, such as mechanical and electrical equipment and systems, are tested or analyzed to ensure they can maintain their operability and functionality after an earthquake. These components are essential for the functioning of a building, and their ability to remain operational during seismic events is crucial to the safety of the building’s occupants and its long-term use.

For example, hospital operating room equipment must remain operable to accommodate the potential influx of patients after an earthquake. Government defense and emergency response facilities must be able to maintain their critical functions after a significant event. These components and facilities undergo seismic certification to safeguard their reliability when they are needed most.

Who Is Qualified to Conduct a Seismic Certification?

Seismic certifications should only be conducted by qualified professionals with the necessary expertise and experience. Typically, this involves a registered structural engineer or professional engineer specializing in seismic design and nonstructural components. These professionals are responsible for reviewing the equipment, analyzing its seismic performance, and ensuring it complies with relevant codes and requirements. In many cases, a manufacturer is responsible for providing the equipment’s certification report based on testing or experience data. However, the final approval and certification should come from a licensed engineer who understands the specific seismic requirements of the project and the jurisdiction in which the equipment will be installed. This ensures the equipment will perform safely and reliably in the event of an earthquake.

The Process of Seismic Certification

Seismic certification is a multi-step process that considers specific equipment, site, and building location details.

- Certification report: The first step in seismic certification is obtaining a seismic certification report. This document outlines the parameters of the certification, including the structural capacity of the nonstructural component to resist seismic forces. Depending on the type of component (active vs. passive), the certification process might include analysis, testing, or experience-based data to prove compliance with seismic standards.

- Site-specific certificate of compliance or OSP preapproval report: Once the necessary equipment is certified, the engineer of record must review the certification and approve it for use on the project site by issuing a certificate of compliance. This document certifies that the equipment meets the necessary seismic standards based on its specific location and expected seismic conditions. For example, the California Health Care Access and Information (HCAI) department, formerly OSHPD, offers a Special Seismic Certification Preapproval (OSP) program that streamlines equipment for use on HCAI projects. This OSP preapproval is becoming a sought-after standard for seismic certification for many facilities, including those outside of California.

- Product label: The equipment must also have a seismic label affixed to it. This label indicates the specific parameters of the seismic certification and serves as a visual confirmation that the equipment is suitable for seismic conditions.

Seismic Code Requirements

The seismic certification process is governed by various building codes, with two key documents being the American Society of Civil Engineers (ASCE) Standard 7 and the International Building Code (IBC). These specify the requirements for seismic design and certification for both structural and nonstructural components.

- ASCE 7 outlines seismic design criteria, including the classification of nonstructural components into two categories: active and passive. Active components involve moving parts and electricity, while passive components are static and do not involve moving parts or electricity. The certification process can vary based on the component type, but both active and passive elements are required to be certified for seismic compliance.

- IBC and ASCE 7 require that seismic certification be specified in the approved construction documents. The structural engineer must verify that the mounting and anchorage of each component comply with seismic standards. This verification is critical for ensuring the safety of the building and its occupants.

Engineering consultants will consider several details during the certification process, including:

- Component importance factor: The component importance factor (Ip) is crucial for determining the level of seismic protection required for a given component. For instance, components related to life safety, such as fire suppression systems, must meet more stringent seismic requirements with a higher factor (Ip = 1.5). On the other hand, less critical components may have a lower factor (Ip=1.0). Understanding which components need to meet these higher standards is vital for the project team.

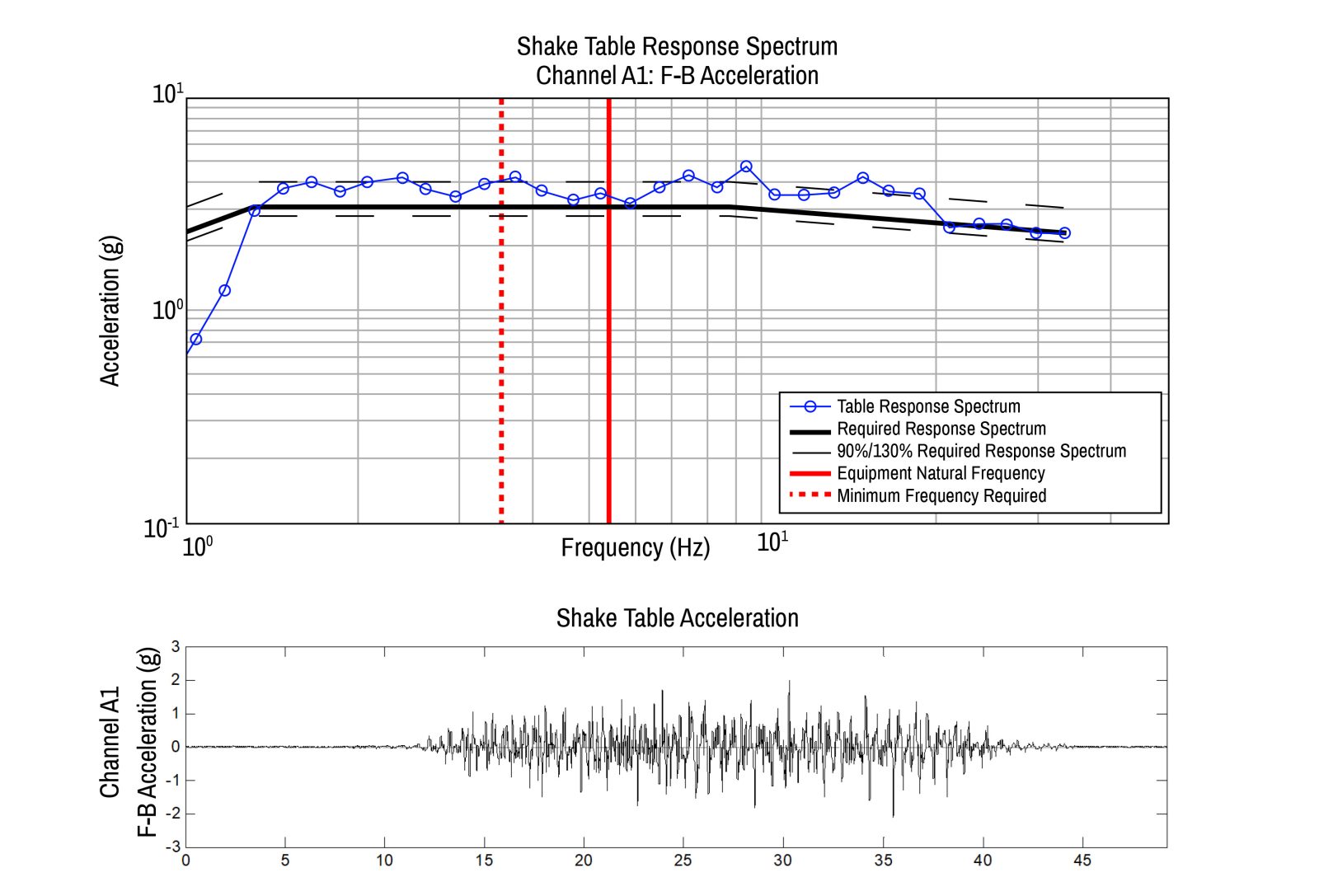

- Testing and analysis: Testing methods like shake-table tests are often employed to simulate seismic forces and assess equipment performance. The equipment is not typically required to be operational during testing, only post-test, except in specific cases like nuclear facilities or other critical systems.

- Jurisdictional variance: Enforcement of seismic certification requirements can vary depending on local building codes and jurisdictions. While seismic certification has been part of the commercial building code since 2000, its enforcement is not uniform across the U.S. Building owners and facility managers must work closely with the project team and the local authority having jurisdiction (AHJ) to ensure compliance with the relevant regulations.

Considerations for Building Owners and Facility Managers

Important considerations for building owners and facility managers include:

- Seismic certification in RFPs: When issuing requests for proposals (RFPs), it’s crucial to clearly specify the seismic certification requirements for all nonstructural components. This ensures that the equipment selected for the project meets the necessary seismic standards and prevents issues during construction. Clarifying expectations early on will also help avoid conflicts between mechanical engineers, owners, and AHJs.

- Voluntary seismic upgrades: In some cases, building owners may choose to voluntarily upgrade their facilities to meet higher seismic standards. While not always required by code, these upgrades can enhance the building’s resilience to earthquakes and ensure the continued operation of critical systems. In some jurisdictions, voluntary seismic retrofits can trigger additional requirements for nonstructural components, but this varies depending on local codes.

- Cost implications: Seismic certification can affect the cost and availability of equipment. While many manufacturers provide certified equipment as part of their offering, some specialized or custom equipment may require additional testing or certification. Building owners should be prepared for potential delays and costs associated with securing certified equipment for their projects.

Recertifying Nonstructural Components and Renewing Approvals

Seismic building codes evolve over time, and critical equipment may require recertification to ensure compliance with the latest standards. This is especially important for systems like emergency power, fire suppression, and hospital equipment, where functionality during and after an earthquake is vital.

There are several instances when recertification may be necessary:

- Code updates: New seismic codes may render older certifications non-compliant, requiring testing or reanalysis to meet updated standards.

- Changes in equipment use: Repurposing equipment for more critical functions may necessitate recertification to meet higher seismic standards.

- Building modifications: Structural changes to the building may alter how nonstructural components are anchored, requiring reassessment of their seismic safety.

To ensure that existing equipment and nonstructural components remain compliant with the latest version of the building code, voluntary programs like HCAI and OSHPD OSPs have expiration dates associated with their pre-approvals. Equipment manufacturers and building owners must keep track of OSP renewal deadlines and engage with seismic certification consultants to review their current compliance, identify potential code changes, and evaluate if further testing and analysis are necessary for their renewal. HCAI keeps an active list of expiration deadlines by category and certification number, with more than 400 currently expired or set to expire by the end of 2025.

Conclusion

Seismic certification is a critical process for ensuring the safety and functionality of nonstructural components in buildings located in earthquake-prone regions. For building owners, equipment manufacturers, and facility managers, understanding the requirements for seismic certification, working closely with the project team, and ensuring clear communication with local authorities are essential steps in ensuring compliance with seismic standards. By prioritizing seismic certification, building owners can safeguard their facilities against the impact of earthquakes and enhance the resilience of their structures for years to come.