Laboratory Testing to Identify Counterfeit Materials in the Construction Industry

The prevalence of counterfeit products and materials has been a growing concern in recent years. With companies aiming to meet increased demand for products while decreasing costs, the market has seen a growing influx of counterfeit products and materials. Supply chain issues, such as those seen in the global recovery from the COVID pandemic, can also accelerate the appearance of more counterfeit materials.

These counterfeit components—which can be anything intended to deceive its buyer or user, often due to the presence of known deficiencies in the product—can lead to critical failure during use. This is especially true of materials used in building and construction.

The counterfeiting challenge

Counterfeiting is a problem across a wide range of industries. While the extent is hard to quantify, the Counterfeit Intelligence Bureau estimates that counterfeit products make up 5-7% of world trade, according to the International Journal of Operations & Production Management. In the construction industry, counterfeit products can impact project safety, schedules, costs, and quality.

When counterfeit materials do make it through the supply chain, customers can find themselves dealing with unforeseen product deficiencies without knowing why. When this occurs, the task at hand is to employ test methods that can help determine whether the product is counterfeit. Numerous laboratory techniques can be employed to answer the fundamental question, “Is my material authentic or counterfeit?”

Laboratory methods to identify counterfeit materials

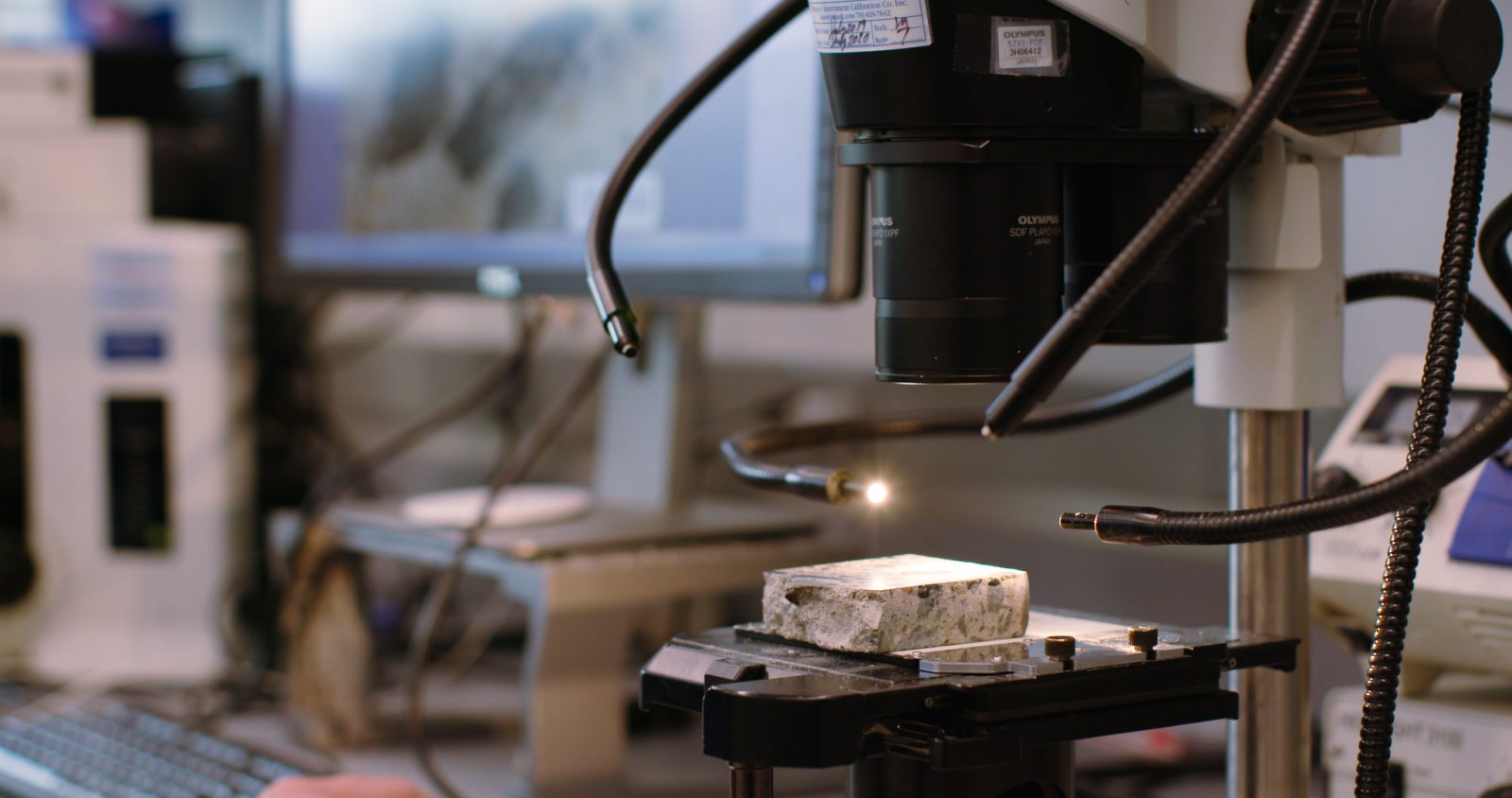

Microscopy

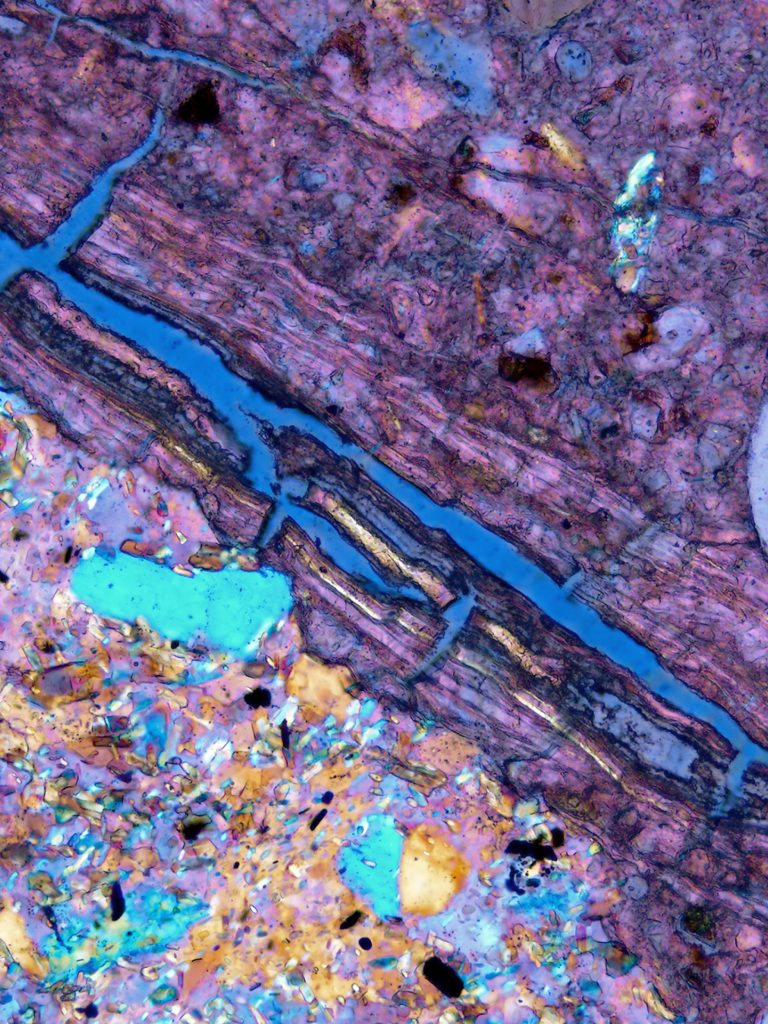

Microscopes allow us to see fine details of a material. From these details, we can look at microstructure, surface texture, transparency and opacity, and other properties of the material of interest. Tools for these methods include:

- Optical or stereomicroscopy

- Scanning electron microscopy

Chemical testing

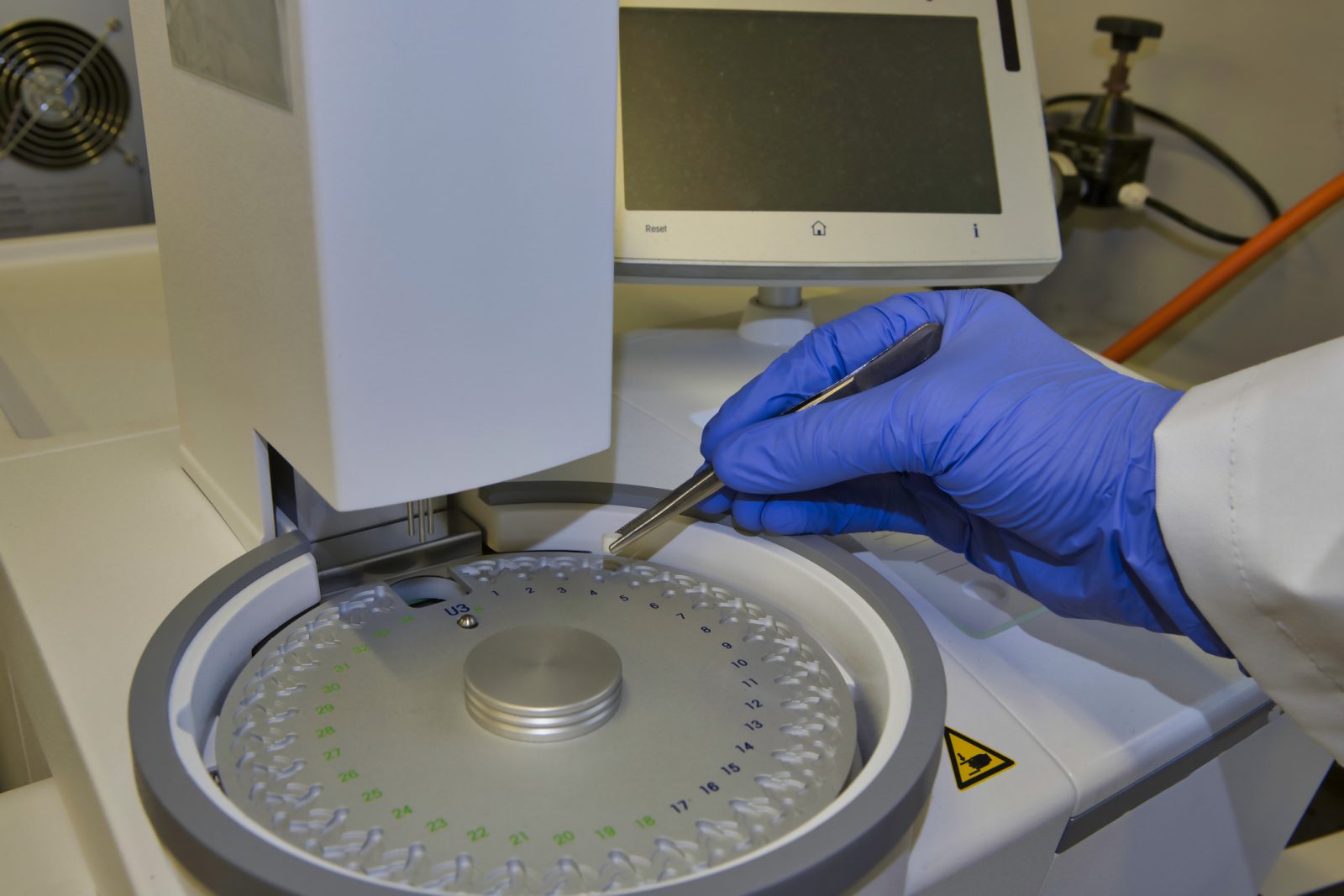

Spectroscopy allows for a chemical analysis of products to determine if their chemical makeup is what it should be. It also allows us to compare the resulting spectrum to a library of known materials. From this information, we can determine what a material is (or isn’t), and look for the presence of contaminants that might impact material performance. Tools for chemical testing methods include:

- Fourier transform infrared spectroscopy (FT-IR)

- Energy-dispersive X-ray spectroscopy (EDS)

- X-ray diffraction (XRD)

Thermal testing

Thermal testing can give insights into the quality of polymers that make up plastics, rubbers, and other materials. Long polymer chains are correlated with higher strength and higher melting points. During manufacturing processes such as mixing, heating, and extruding, the polymer chain length will, on average, decrease due to physical or thermal damage to the chains. Because of this, it is important to start the manufacturing process with the highest-quality (i.e., longest-chain) polymers. Counterfeit or sub-quality products are often made with cheaper, poor-quality starting materials that then further degrade throughout the manufacturing process. Thermal analysis to determine degradation temperature can help distinguish between authentic and counterfeit materials. Tools for these methods include:

- Thermogravimetric analysis (TGA)

- Differential scanning calorimetry (DSC)

- Thermomechanical analysis (TMA)

- Dynamic mechanical analysis (DMA)

Environmental testing

Initial properties may be similar, but a counterfeit product may not have the longevity necessary for the lifetime of the authentic material. Accelerated environmental testing can provide insight into the durability of a product over time in the field, and can show early deterioration of a counterfeit material compared to the authentic product. Environmental testing can also evaluate the robustness of materials when combined with other analysis methods to monitor performance over time. Tools for these approaches include:

- QUV accelerated weathering machine

- Xenon arc accelerated weathering machine

Mechanical testing

Mechanical testing allows us to determine if a material meets the strength requirements noted in a product specification sheet. Fatigue testing can be used to measure the longevity of a product. Tools for these methods include:

- Tension/compression testing

- Fatigue analysis

Comparing counterfeit testing results

Testing potentially counterfeit materials is all about comparison—to known authentic materials, to known counterfeit materials, and to mechanical test results and technical data sheets for the authentic product.

It is important to tackle the question of counterfeit materials by employing more than one laboratory technique. Each method interrogates a different aspect of the material. While one test may show similarities between two products, other tests may indicate differences between authentic materials and suspected counterfeit materials that confirm the material as counterfeit.

We can employ numerous laboratory techniques to answer the fundamental question, “Is my material authentic or counterfeit?”

Case in Point: Rubber flashing degradation

Three pieces of rubber flashing were submitted to SGH’s Applied Science & Research Center to determine if the degradation seen in in-use flashing was due to regular exposure to the elements or if it was a counterfeit material from a non-U.S. manufacturer.

Applied researchers and materials scientists compared FT-IR spectra of several samples—the used flashing, unused “attic stock” on the project site, and a known U.S. product—and found that all the materials were similar in chemical makeup. If testing had stopped there, the conclusion may have been that the materials have the same chemical makeup and are the same.

However, additional thermal testing revealed that the degradation onset temperatures were different for the authentic and suspected counterfeit materials. This finding provided evidence that the suspected counterfeit material could have been manufactured differently than the authentic material, and would therefore have the same chemical makeup but inferior physical properties.

Putting these testing results together, the researchers were able to confirm material differences between the authentic and counterfeit materials that they may not have been able to in the absence of multiple types of testing.

Case in Point: Failed window laminate products

Amid a years-long investigation into window failure issues on a project site, the window manufacturer released a statement warning of known counterfeit laminate products in the industry that were impacting performance. The warning included observed effects of using the counterfeit laminate product, such as material warping. This physical observation can be related back to a material’s polymer makeup, which can be characterized by thermal properties such as the coefficient of thermal expansion (CTE) or chemical properties such as polymer structure.

Researchers employed thermal testing (i.e., TMA) to compare the questioned material’s CTE to that of an authentic laminate product. The results of TMA testing showed that the two tested materials display similar CTE values over the tested temperature ranges. FT-IR spectra of the questioned material and authentic laminate product also showed that both materials were similar in chemical composition.

Putting these results together, the researchers were able to support the conclusion that the questioned material was similar to the authentic product, and thus not counterfeit.