Water Research Foundation, CFRP Renewal of Prestressed Concrete Cylinder Pipe, Project 4352

Scope/Solutions

Prestressed-concrete cylinder pipe (PCCP) makes up a significant portion of pipelines for the world’s water, wastewater, and cooling water systems. Distress to PCCP can include broken wires, cracked cores, or corroded steel cylinders. Renewal of distressed PCCP may be accomplished by lining the pipe with carbon fiber-reinforced polymer (CFRP), eliminating the need for excavation and minimizing service disruption. Under contract with the Water Research Foundation, SGH conducted the research that formed the technical basis of the American Water Works Association (AWWA) standard in this area.

CFRP liners are often used for renewal and strengthening of PCCP, but standards are needed to ensure strength, reliability, and durability of the designs and quality and consistency of material selection and installation. To develop a standard for CFRP Renewal and Strengthening of PCCP under the auspices of AWWA, the Water Research Foundation sponsored research to create the technical basis for such a standard. SGH partnered with utilities, CFRP repair contractors, CFRP manufacturers, and PCCP manufacturers to perform this analytical and experimental research, including following:

- Literature review of CFRP durability and development of material adjustment and time-effect factors

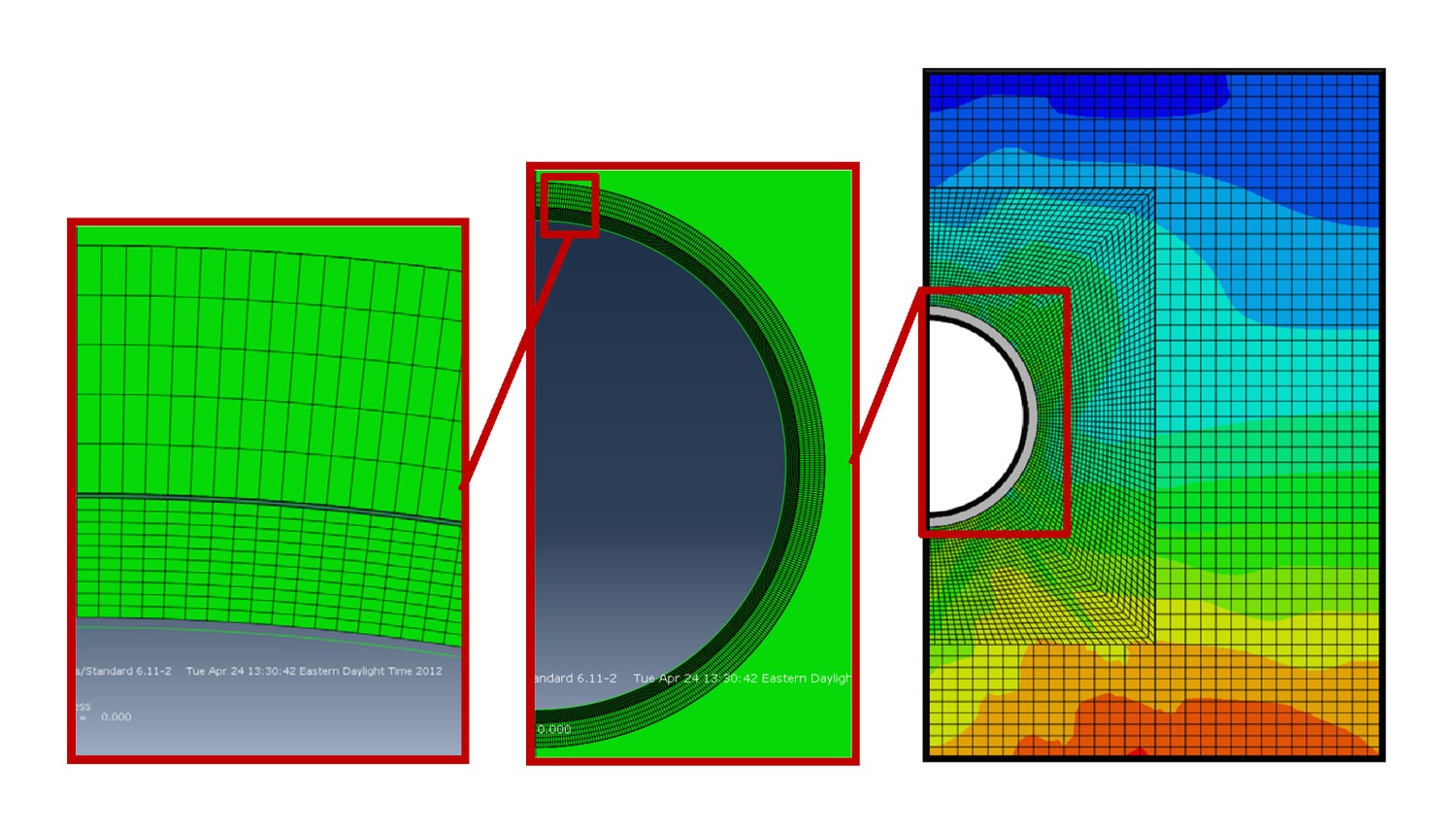

- Nonlinear finite element analysis of pipe-soil interaction that accounts for degradation of CFRP-lined PCCP throughout its service life, and analysis of bending and buckling behaviors

- Reliability analysis of design limit states and development of load and resistance factors for design of CFRP liners for renewal of PCCP

- Full-scale experimental testing of CFRP-lined PCCP with broken wires subjected to internal hydrostatic pressure and three-edge bearing loads

Our research revealed new failure modes and the results were used to develop provisions for the AWWA standard for CFRP Renewal and Strengthening of PCCP.

Project Summary

Key team members